The plastic bottle is

used everywhere and every day. During hot summer seasons, everyone needs water

to fulfil their thirst. But the only product helps to carry water easily to all

places is the plastic bottle. The plastic bottle is strong, less weight,

portable and stylish to carry, etc.. The cap of the plastic bottle is more

important. It prevents, the dust to enter into the bottle. The size of cap

differs with the design of the bottle. There are some models of caps that are

screw type or open/ close type with respective of the design of the bottle. We

produce the cap molds by demand and expectations of the customers.

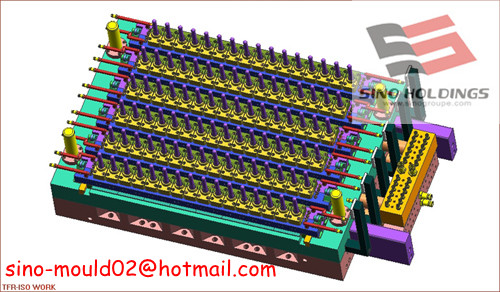

The cap is

manufactured by injection molding machine which uses the plastic bottle cap

mold. The mold used can have more number of cavities as required by the

manufacturer. The cavities of the cap molds are adjustable to various

dimensions with respective to the bottle design. The raw materials are fed to

machine through the hopper and it is compressed by the reciprocating screw.

Then it is melted by the heaters around the injection cylinders. The volume of

injection cylinder is designed to fill all cavities of the mold during the

injection process. The plastic bottle cap moulds

is always made of stainless steel to avoid corrosion. The mold is to be

maintained regularly to avoid corrosions and other surface etching factors. Some

of molding defects are blistered, burn marks, color streaks, flash, embedded

contaminates, knit lines and sink marks etc.. These defects are to be

identified and cleared periodically to produce the best quality plastic

product. The blistering of mold can be avoided by maintaining constant cooling

process in the mold during the plastic injection process of cap molding. Our

cap molds are designed in a manner that the cavities are adjusted by the

automated machines. This is our latest trend set in the global market. we

assure you that our molds has life long durability as it was made by corrosive

resistant alloys.

If you want to know

more information regarding the mold company, then you can refer through the

company website http://preformmold.sosblogs.com/The-first-blog-b1/Professional-Bottle-Preform-Mould-Maker-in-China-b1-p20.htm

.